What are the advantages of Infineon is SOI driver chips?

Publish:IC chip, PCB, PCBA, integrated circuit and other electronic components-Shenzhen Hao Qi Core Technology Co., Ltd Time:2022-08-25 Views:209

What are the advantages of Infineon‘s SOI driver chips? Below we will analyze it in detail.

Advantage 1: Excellent negative pressure resistance of VS feet

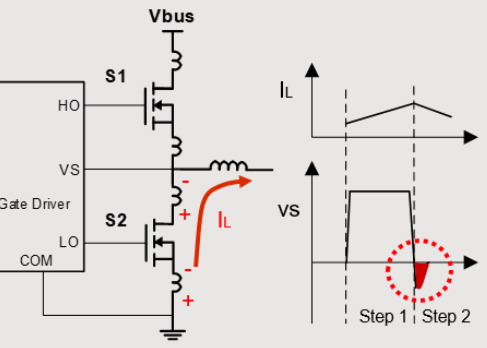

Today‘s high power frequency converters and drives carry larger load currents. As shown in the figure below: Due to the parasitic inductance in the power loop (mainly generated by the package leads of the power device and the PCB traces), the voltage of the VS pin in the circuit will change from the high-voltage bus voltage (when S1 is on and S2 is off) to low Negative pressure to ground (when S1 is closed). The red part of the waveform on the right side of Figure 1 is the transient negative voltage generated by the VS pin in the half-bridge inductive load circuit.

This transient negative pressure spike will cause the driver chip to malfunction and damage the power device, and sometimes directly damage the driver chip. This negative voltage spike becomes larger and larger at high currents and high-speed switching, especially when using wide-bandgap devices: silicon carbide and gallium nitride. The device‘s ability to withstand negative pressure has become a key factor in selecting high-voltage driver chips in these application fields.

In Infineon‘s SOI technology, the active area of the chip and the substrate are insulated, and there are no parasitic transistors and diodes like conventional silicon technology drive chips, so the above-mentioned problems caused by negative VS voltage will not occur.

Infineon‘s SOI high-voltage driver chip has a very high negative pressure capability, and the VS pin can withstand a voltage of negative 100 V for 300ns.

Advantage 2: Very low level shift circuit loss

The level shift circuit transmits the switching signal at the low voltage end to the high voltage end, and the energy consumed during the transmission process determines the loss of the level shift circuit. As the switching frequency increases, the loss of the level shift circuit accounts for an increasing proportion of the loss of the entire driver chip.

The level-shift circuit of Infineon‘s SOI high-voltage driver chip consumes very little energy. The ultra-low loss of the driver chip greatly improves the design flexibility of high-frequency applications, and also improves the efficiency of the system, thereby improving the reliability of the system and the life of the product.

Advantage 3: Bootstrap diode integrated inside the chip

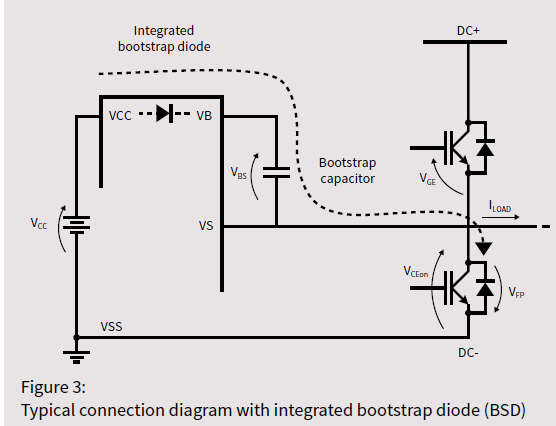

The floating terminal circuit of the high-voltage driver chip generally uses the bootstrap power supply, which is a simple and low-cost power supply scheme. But conventional silicon technology high-voltage driver chips must add bootstrap diodes, or use low-efficiency bootstrap MOSFETs integrated inside the chip and additional internal control circuits to achieve bootstrap power supply.

Infineon‘s SOI driver chip integrates an ultra-fast recovery bootstrap diode, excellent reverse recovery characteristics and a dynamic resistance of less than 40 ohms, which greatly expands the use range of the chip and can drive larger capacity power devices without overheating, thereby simplifying circuit design and reducing system cost.

The figure shows the bootstrap power supply circuit, which consists of a bootstrap diode and capacitor. The bootstrap power supply is a typical power supply method for the floating terminal circuit of the high-voltage driver chip in the level shift mode.

- CONTACT US

-

-

Contact Person: Mr. Andy Luo

Job Title: Sales

Business Phone: +(86) 13632701337 (electronic component) , +(86)13632701337 (Automation Part )

WHATSAPP: +86 13632701337 (electronic component) , +(86)13632701337 (Automation Part )

Wechat: +86 13632701337 (electronic component) , +(86)13632701337 (Automation Part )

Skype: happylowping

ICQ: 458036258

Email:andyluo@kinglionski.com (electronic component) , andyluo@kinglionski.com (Automation Part )