Design of lithium battery charging circuit based on BQ34Z100-G1

Publish:IC chip, PCB, PCBA, integrated circuit and other electronic components-Shenzhen Hao Qi Core Technology Co., Ltd Time:2022-01-09 Views:482

With the increasing popularity of electric bicycles and electric motorcycles, consumers have also put forward higher requirements for the battery life of the battery pack. Extending the battery pack life allows the vehicle to travel further without requiring frequent recharging.

Lithium-ion (Li-ion) battery pack endurance can be improved in two ways: by increasing the total battery capacity or by improving energy efficiency. Increasing the total battery capacity means using more or better performing cells, which can significantly increase the overall cost of the battery pack. And improving energy efficiency provides designers with more usable energy without increasing capacity. There are two ways to improve energy efficiency: improve state of charge accuracy and/or reduce current consumption.

To get longer runtime, you need to draw as much energy as possible from the battery pack; however, if overdischarge occurs, the battery will be permanently damaged. Accurate knowledge of battery capacity or state-of-charge information is critical to avoid overdischarging the battery. There are three ways to accurately measure state of charge:

Battery voltage measurement.

Coulomb counting.

Technology.

Battery voltage measurement is the easiest method, but it also has low accuracy for overload conditions. Coulomb counting measures and integrates current over time. However, achieving better state-of-charge accuracy requires periodic full-to-idle learning cycles, and state-of-charge accuracy will be affected by self-discharge and standby current. Low temperature and aging batteries also reduce the accuracy of the state of charge. Impedance Track technology directly measures the effects of discharge rate, temperature, lifetime, and other factors by learning battery impedance. As a result, the Impedance Track method gives you better state-of-charge measurement accuracy even when the battery is aging and temperature is too low.

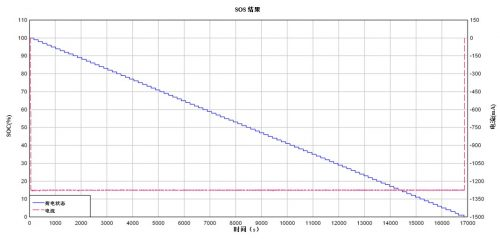

Our accurate measurement and 50µA standby current, 13S, 48V Li-Ion battery pack reference design uses the BQ34Z100-G1, an Impedance Track fuel gauge for Li-Ion, lead-acid, NiMH, and NiCd batteries, independent of Batteries in series battery configuration work. This design supports external voltage translation circuits. The circuit is automatically controlled to reduce system power consumption and provide the user with longer runtime per charge without worrying about possible damage from over-discharge. Due to the low current consumption, the overall system has very limited influence on the measurement results. Therefore, we will read data directly from the BQ34Z100-G1 through BQStudio at a constant discharge current at room temperature. Figure 1 shows the discharge state of charge test results.

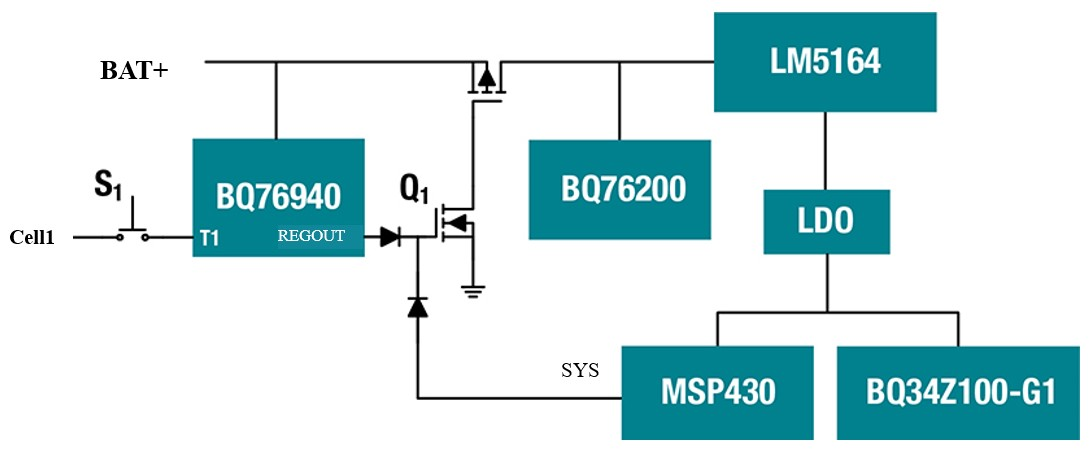

The second way to improve energy efficiency is to reduce current consumption. An accurate measurement reference design introduces an optimized bias supply solution, as shown in Figure 2.

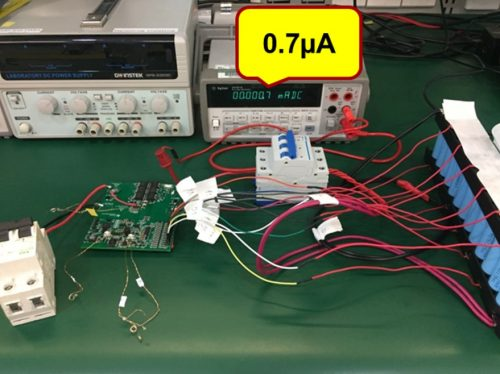

This design utilizes our new LM5164 as an auxiliary power supply. The 100 V LM5164 is a wide input, low quiescent current step-down DC-DC converter that protects the system from potential transients from a nominal 48 V battery and provides power for 3.3 V microcontrollers (MCUs) and BQ34Z100- G1 powered. The input to the LM5164 is controlled by two signals: REGOUT from the BQ76940 and SYS from the MSP430™ MCU. Either of these two signals is high and will turn on Q1 and enable the input to the LM5164 - thus enabling the MCU power supply. When the board is fresh from the factory and the battery management board is powered up for the first time, it is in factory mode. With the exception of the BQ76940, the entire system is unpowered, enabling factory-mode current consumption as low as 5-µA. Press button S1 to set REGOUT high and power on the system. When the MCU powers up, it sets SYS high. Whether the BQ76940 is in shutdown mode or normal mode, the entire system has a stable power supply.

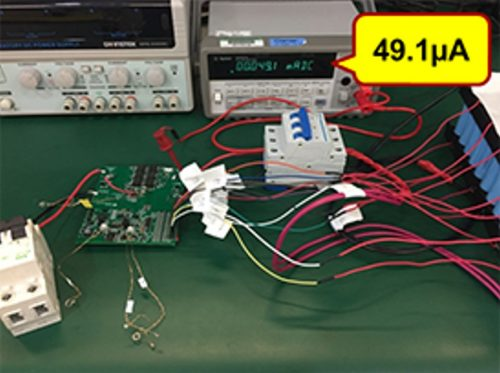

You need to power on the MCU to enable all e-bike battery pack functions in standby mode, including charger connection/removal and load connection/removal. Q1 should power up. To reduce standby mode current consumption, the BQ76940 is set to shutdown mode via I2C command. So SYS is high, keeping Q1 energized. The LM5164 is set to a low switching frequency to reduce switching losses, while the MSP430 MCU is in low power mode. All charger attach/detach and load attach/detach detections are implemented through firmware. Standby current consumption is typically 50µA, as shown in Figure 3. Figure 4 shows the factory mode current consumption of the motherboard.

in conclusion

In summary, the reference design enables accurate state-of-charge measurement (via the BQ34Z100-G1) and reduced standby and factory-mode current consumption (via an optimized bias supply solution). Together, these two solutions improve the energy efficiency of e-bike battery packs, providing users with longer usage times.

- CONTACT US

-

-

Contact Person: Mr. Andy Luo

Job Title: Sales

Business Phone: +(86) 13632701337 (electronic component) , +(86)13632701337 (Automation Part )

WHATSAPP: +86 13632701337 (electronic component) , +(86)13632701337 (Automation Part )

Wechat: +86 13632701337 (electronic component) , +(86)13632701337 (Automation Part )

Skype: happylowping

ICQ: 458036258

Email:andyluo@kinglionski.com (electronic component) , andyluo@kinglionski.com (Automation Part )